Highly Integrated: Incorporates 8 core components, delivering a complete "plug-and-play" joint solution.

Powerful Performance: Provides a continuous output torque of up to 35N.m, handling various load scenarios.

Compact & Lightweight: With a 70mm outer diameter and weighing only 0.77kg, it achieves excellent power density and space efficiency.

Simplified Development: Significantly reduces mechanical and electrical complexity, accelerating the journey from concept to prototype.

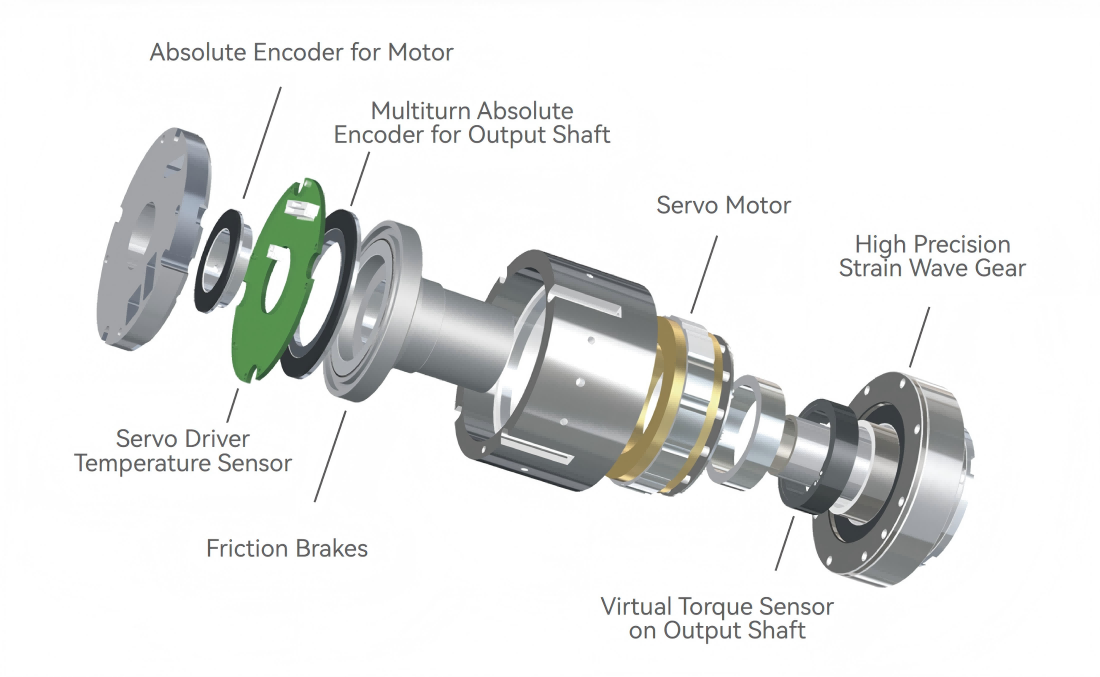

8 Core Components for eRob Series Robot Joint Actuator

The eRob series robotic joint module is a highly integrated all-in-one solution that combines eight core components: a servo motor, high-precision harmonic gear reducer, dual absolute encoders, servo drive, friction brake, temperature sensor, and virtual torque sensor. This innovative design eliminates the need for complex external component selection and integration, providing users with a plug-and-play power unit that significantly simplifies the robotics development process. It is an ideal choice for building high-performance collaborative and humanoid robots.

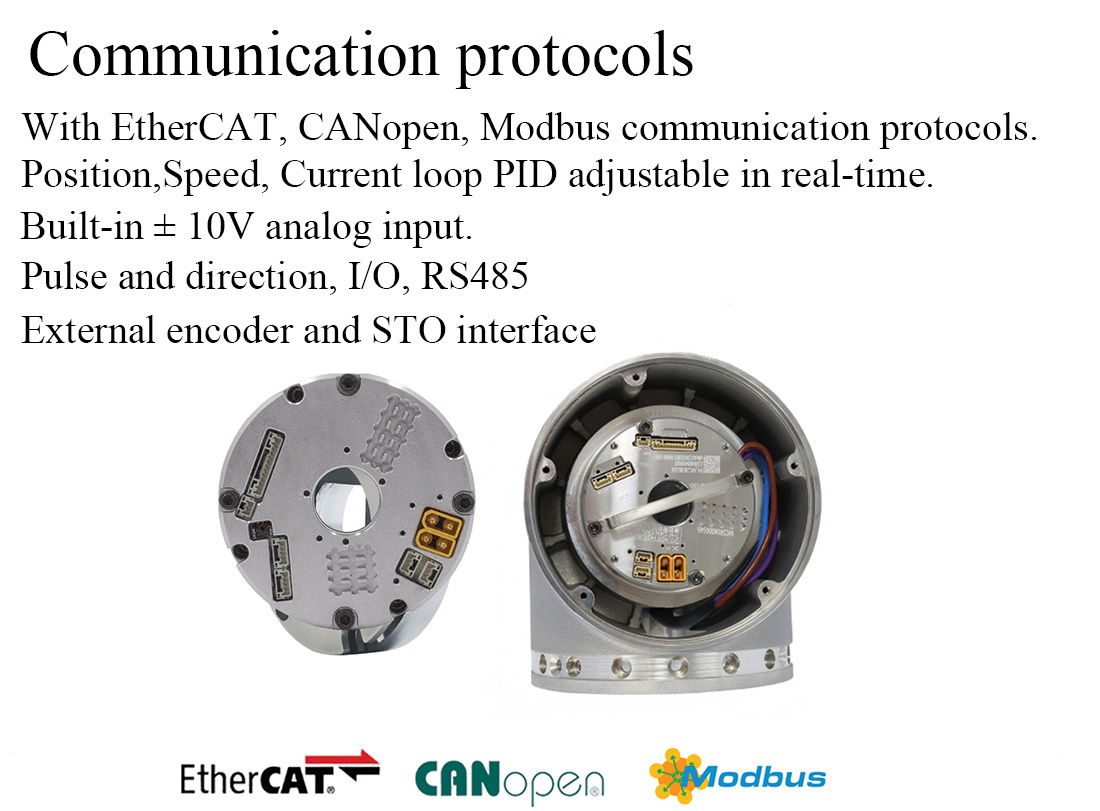

The eRob series robot joint actuator features a built-in servo driver supporting multiple industrial communication protocols. It is compatible with EtherCAT, CANopen, and Modbus for seamless integration into various control systems. The driver allows for real-time adjustment of the Position, Speed, and Current loop PID parameters, ensuring precise motion control. Additional interface flexibility is provided through built-in ±10V analog input, Pulse and Direction inputs, I/O ports, and RS485. It also includes an external encoder interface and a Safety Torque Off (STO) interface for enhanced functionality and safety.

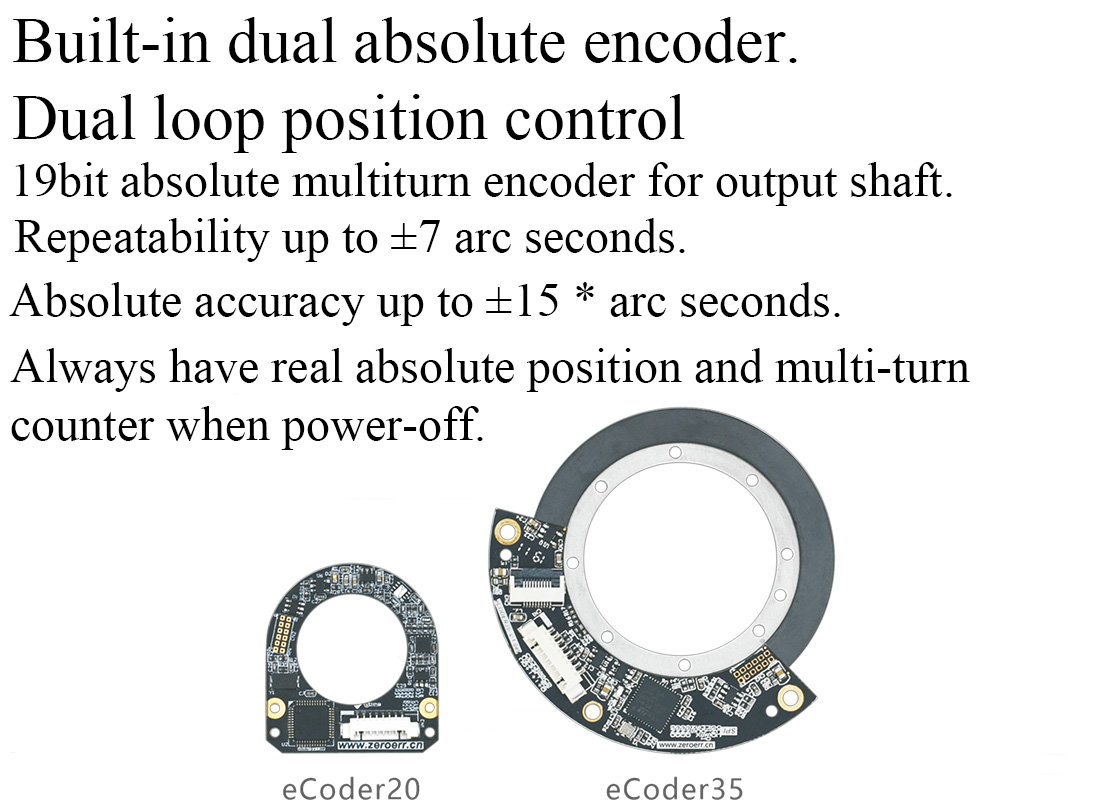

This robotic joint module incorporates a dual absolute encoder system for exceptional accuracy and reliability. The output shaft is equipped with a 19-bit absolute multi-turn encoder, enabling repeatable positioning with a repeatability of up to ±7 arc seconds. The system achieves an absolute accuracy of up to ±15 arc seconds. A key advantage is that the module always retains the real absolute position and multi-turn counter even after a power-off event, eliminating the need for homing procedures upon restart and ensuring immediate operational readiness.

The eRob series actuator features an internally integrated friction brake designed for smooth and stable operation. Its key benefits include zero backlash and no physical gap, contributing to highly precise motion control. Unlike traditional brakes, it requires no corrective movement upon power-on, reducing wear and tear for increased longevity and maintenance-free performance. This robust brake mechanism can also be reliably utilized as an Emergency Stop function, enhancing the overall safety of the robotic system.

| Model | eRob70I | |||

| Strain wave gear-ratio | 14-50 | 14-80 | 14-100 | 14-120 |

| Peak torque for start and stop (Nm) | 23 | 30 | 36 | 36 |

| Permissible max. value at average load torque (Nm) | 9 | 14 | 14 | 14 |

| Rated torque (Nm) | 7 | 10 | 10 | 10 |

| Permissible maximum momentary torque (Nm) | 46 | 61 | 70 | 70 |

| Max. output rotational speed (RPM) | 60 | 37.5 | 30 | 25 |

| Motor power (W) | 100 | 100 | 100 | 100 |